ហើយយើងនឹងជួយអ្នកដោះស្រាយវា

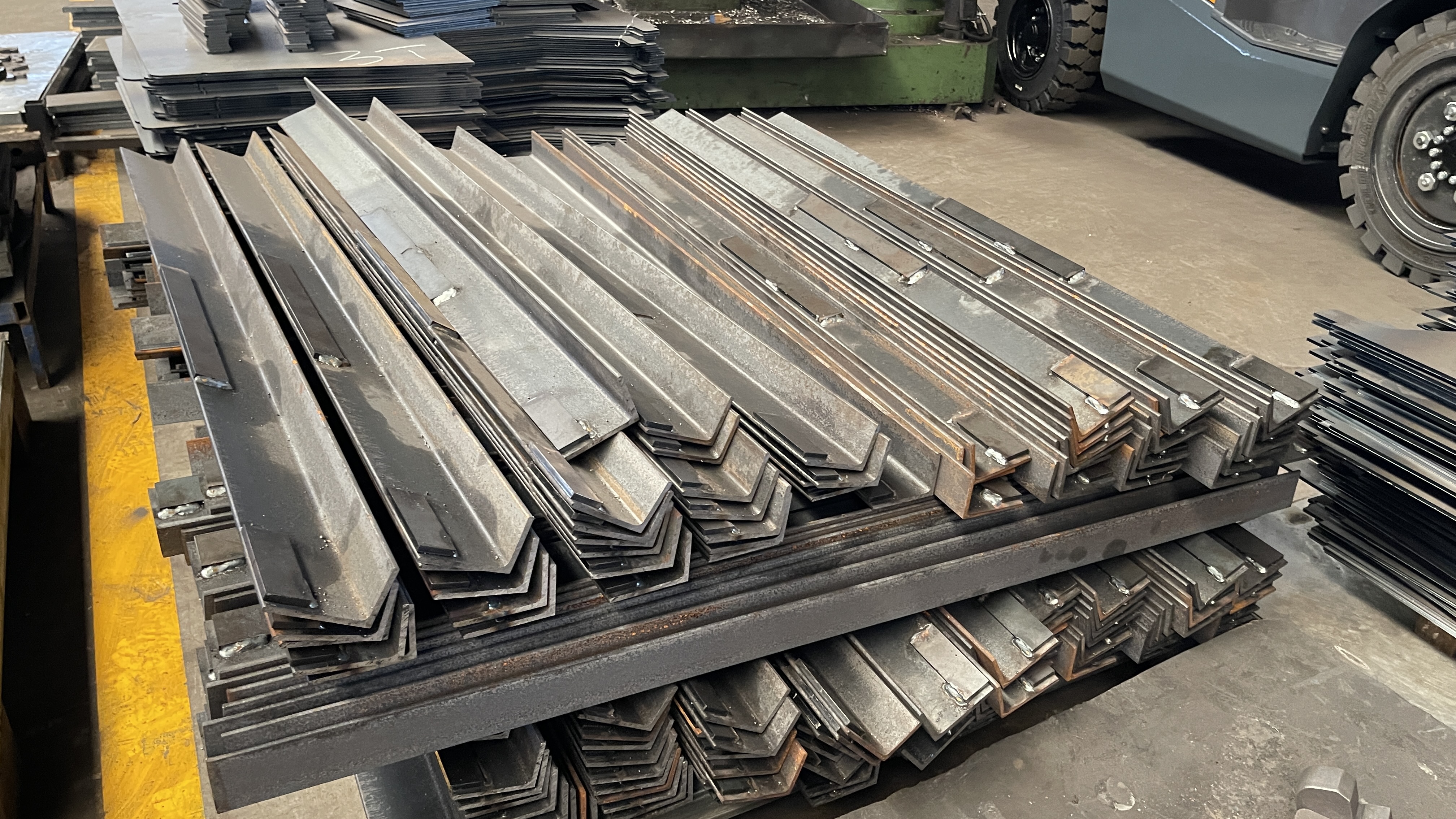

នៅពេលជ្រើសរើសសម្ភារៈសម្រាប់ដំណើរការកាត់ វាជាការសំខាន់ណាស់ក្នុងការពិចារណាលើលក្ខណៈសម្បត្តិ និងលក្ខណៈជាក់លាក់នៃសម្ភារៈ ក៏ដូចជាតម្រូវការនៃផលិតផលចុងក្រោយ។ ខាងក្រោមនេះជាការពិចារណាទូទៅមួយចំនួនសម្រាប់ការជ្រើសរើសសម្ភារៈក្នុងដំណើរការកាត់៖

ភាពរឹង៖ សម្ភារៈដែលមានភាពរឹងខ្ពស់ ដូចជាលោហធាតុ និងផ្លាស្ទិចរឹង អាចត្រូវការឧបករណ៍កាត់ដែលមានភាពធន់នឹងការពាក់ខ្ពស់។

កម្រាស់៖ កម្រាស់នៃសម្ភារៈនឹងមានឥទ្ធិពលលើជម្រើសនៃវិធីសាស្ត្រកាត់ និងឧបករណ៍។ សម្ភារៈក្រាស់ជាងអាចត្រូវការឧបករណ៍ ឬវិធីសាស្ត្រកាត់ដែលមានថាមពលខ្លាំងជាង។

ភាពរសើបចំពោះកំដៅ៖ សម្ភារៈមួយចំនួនងាយនឹងប្រតិកម្មទៅនឹងកំដៅដែលបង្កើតក្នុងពេលកាត់ ដូច្នេះវិធីសាស្ត្រដូចជាការកាត់ដោយទឹក ឬការកាត់ដោយឡាស៊ែរ អាចត្រូវបានគេពេញចិត្ត ដើម្បីកាត់បន្ថយតំបន់ដែលរងផលប៉ះពាល់ដោយកំដៅ។

ប្រភេទសម្ភារៈ៖ វិធីសាស្ត្រកាត់ផ្សេងៗគ្នាអាចសមស្របសម្រាប់សម្ភារៈជាក់លាក់។ ឧទាហរណ៍ ការកាត់ឡាស៊ែរត្រូវបានគេប្រើជាញឹកញាប់សម្រាប់លោហៈ ខណៈពេលដែលការកាត់ដោយប្រើទឹកគឺសមស្របសម្រាប់សម្ភារៈជាច្រើនប្រភេទ រួមទាំងលោហៈ ផ្លាស្ទិច និងសមាសធាតុ។

ការបញ្ចប់ផ្ទៃ៖ ការបញ្ចប់ផ្ទៃដែលចង់បាននៃសម្ភារៈកាត់អាចមានឥទ្ធិពលលើជម្រើសនៃវិធីសាស្ត្រកាត់។ ឧទាហរណ៍ វិធីសាស្ត្រកាត់ដែលមានជាតិសំណឹកអាចបង្កើតគែមរដុបជាងបើប្រៀបធៀបទៅនឹងការកាត់ដោយឡាស៊ែរ។

ដោយពិចារណាលើកត្តាទាំងនេះ ក្រុមហ៊ុនផលិតអាចជ្រើសរើសសម្ភារៈសមស្របបំផុតសម្រាប់ដំណើរការកាត់ ដើម្បីសម្រេចបានលទ្ធផលដែលចង់បាន។

| ដែកថែប | ដែកអ៊ីណុក | យ៉ាន់អាលុយមីញ៉ូម | ទង់ដែង |

| សំណួរទី២៣៥ - ច | ២០១ | ១០៦០ | H62 |

| សំណួរទី២៥៥ | ៣០៣ | ៦០៦១-T៦ / T៥ | H65 |

| ១៦លាន | ៣០៤ | ៦០៦៣ | H68 |

| 12CrMo | ៣១៦ | ៥០៥២-O | H90 |

| # ៤៥ | ៣១៦លីត្រ | ៥០៨៣ | C10100 |

| ២០ ក្រាម | ៤២០ | ៥៧៥៤ | C11000 |

| សំណួរទី១៩៥ | ៤៣០ | ៧០៧៥ | C12000 |

| សំណួរទី៣៤៥ | ៤៤០ | 2A12 | C51100 |

| S235JR | ៦៣០ | ||

| S275JR | ៩០៤ | ||

| S355JR | ៩០៤លីត្រ | ||

| SPCC | ២២០៥ | ||

| ២៥០៧ |

ប្រសិនបើអ្នកមិនទាន់មានអ្នករចនាអាជីពដើម្បីបង្កើតឯកសាររចនាផ្នែកដែលមានជំនាញវិជ្ជាជីវៈសម្រាប់អ្នកទេ នោះយើងអាចជួយអ្នកក្នុងកិច្ចការនេះបាន។

អ្នកអាចប្រាប់ខ្ញុំពីការបំផុសគំនិត និងគំនិតរបស់អ្នក ឬធ្វើគំនូរព្រាង ហើយយើងអាចប្រែក្លាយវាទៅជាផលិតផលពិតបាន។

យើងមានក្រុមវិស្វករជំនាញដែលនឹងវិភាគការរចនារបស់អ្នក ណែនាំការជ្រើសរើសសម្ភារៈ និងការផលិត និងការផ្គុំចុងក្រោយ។

សេវាកម្មគាំទ្របច្ចេកទេសតែមួយកន្លែងធ្វើឱ្យការងាររបស់អ្នកមានភាពងាយស្រួល និងងាយស្រួល។

ប្រាប់យើងពីអ្វីដែលអ្នកត្រូវការ

សមត្ថភាពរបស់យើងអនុញ្ញាតឱ្យយើងបង្កើតសមាសធាតុក្នុងរាង និងរចនាប័ទ្មផ្ទាល់ខ្លួនជាច្រើនប្រភេទ ដូចជា៖

- ការផលិតគ្រឿងបន្លាស់រថយន្ត

- គ្រឿងបន្លាស់អវកាស

- គ្រឿងបន្លាស់ឧបករណ៍មេកានិច

- គ្រឿងបន្លាស់ផលិតកម្ម